What Is Bead Blasting?

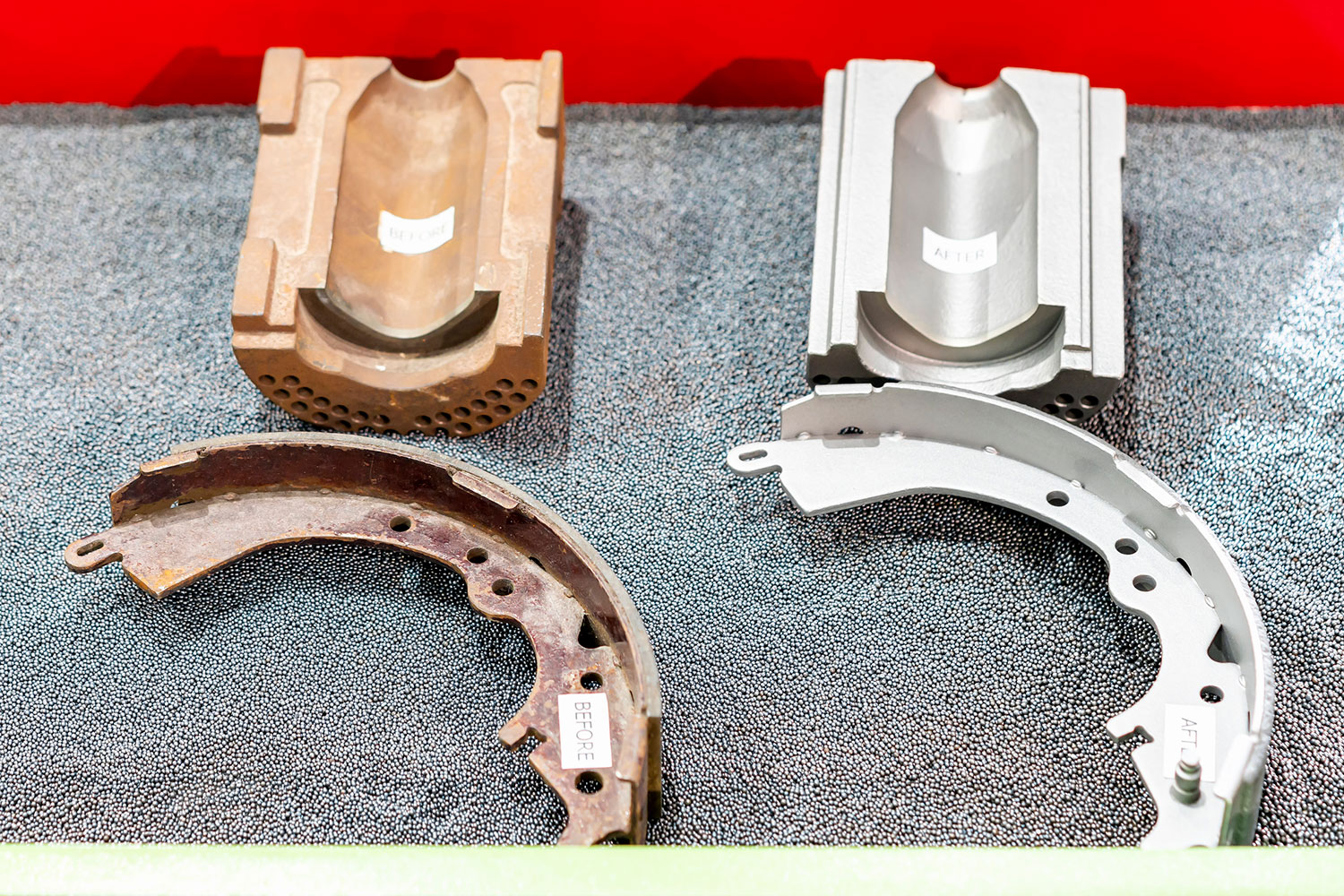

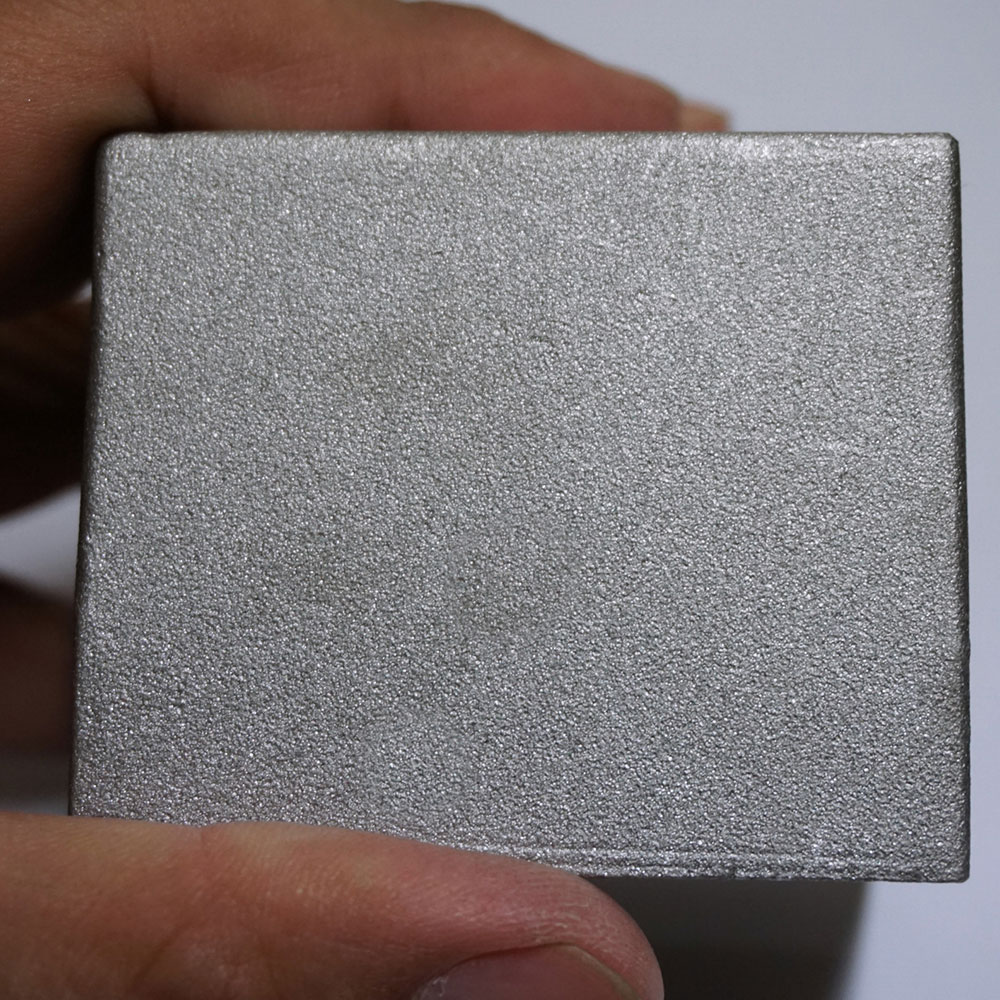

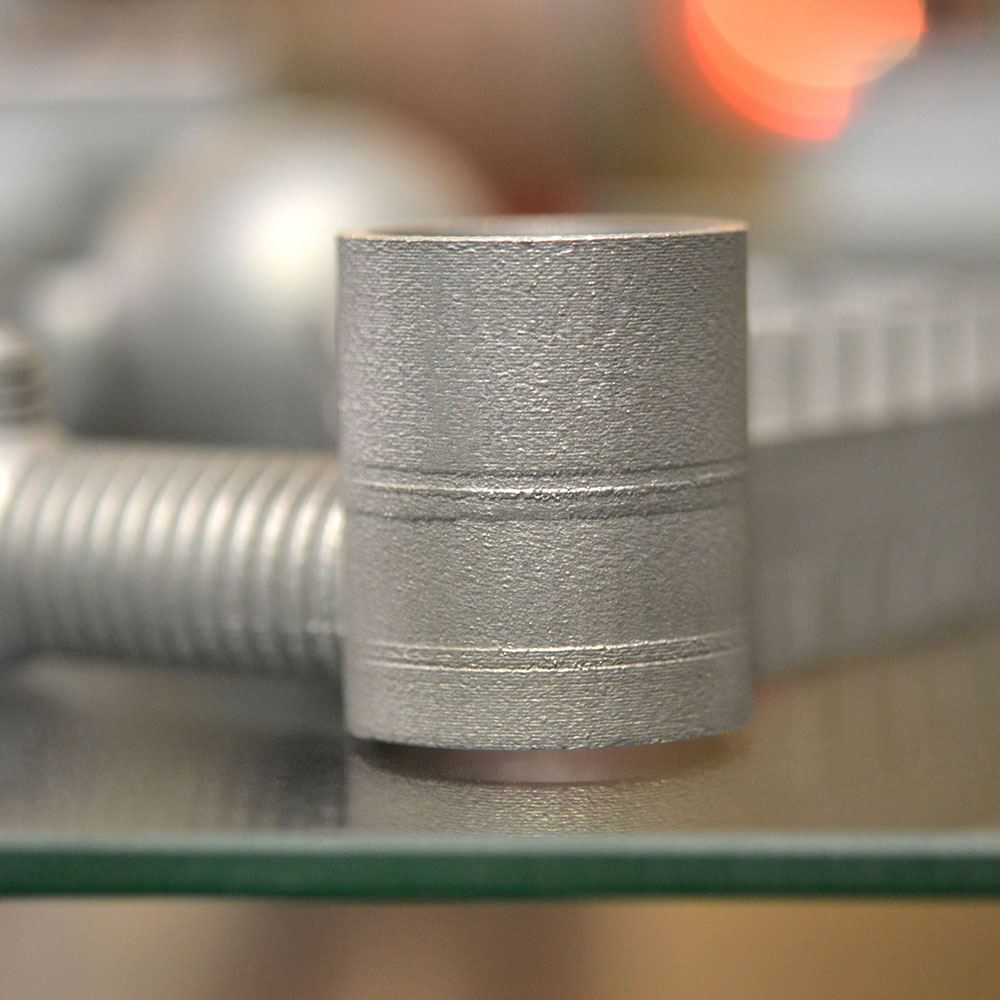

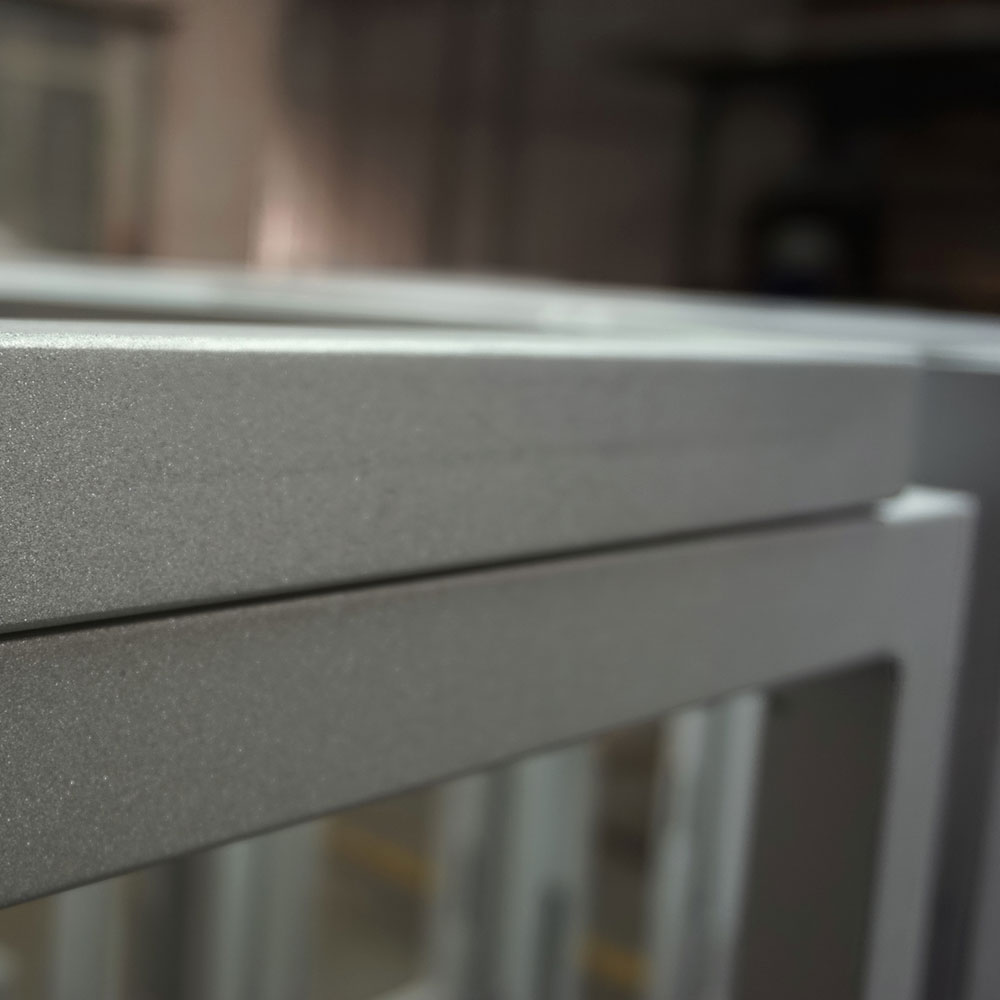

Bead blasting is a technique for surface preparation using beads (usually glass) propelled at controlled pressure. Bead blasting thoroughly cleans and smooths the impacted surface without cutting or damaging the metal unlike other harsher blasting methods. This uniform satin or matte finish not only looks good but also helps prepare the article for further treatment, such as painting, coating, plating, etc.

Common Bead Blasting Applications

Bead blasting gives a lot of benefits, especially for projects where precision and appearance matter.

- Gentle cleaning that protects delicate surfaces.

- Finishing that is consistent, smooth, and does not damage base material.

- Improves coating and paint adhesion.

- It can enhance the looks of decorative and functional elements.

- Suitable for Steel, Aluminium Tehnology, and delicate shapes.

Why our customers come to us

We know many customers have faced issues before finding us. Paint or coatings don’t stick properly. Surfaces peel or corrode due to poor adhesion. There are also times when delicate parts have suffered harm, abrasive blasting has made a mess of things, and surfaces have ended up looking patchy and inconsistent. Using bead blasting technique will solve the issues of blasting. Whatever your needs, we’re offering a reliable solution that gets it right first time whether it is to protect sensitive parts, require quick turnaround or high-quality decorative finish.

Get a Bead Blasting Quote

You can contact Viper Shotblasting for bead blasting services if you are based in Derbyshire, South Yorkshire, Lincolnshire and Midlands. Contact us today to discuss your project and request a free, no-obligation quote.

- Uniform & High-Quality Finish

- Quality and Consistency Assurance

- Proper and Specialised Equipment

- Quick Turnaround and Time Savings

- Safety and Environmental Responsibility

- Competitive Pricing

Bead Blasting Frequently Asked Questions

- What are the benefits of bead blasting for metal surfaces?

- Which materials and components are suitable for bead blasting?

- Is bead blasting safe for delicate or precision parts?

- How does bead blasting compare to sandblasting or shot blasting?

- How long does bead blasting take, and what is the typical turnaround time?

- Will there be any residue left on the surface after bead blasting?

- What finish can I expect from bead blasting?

Tired of dull or uneven surfaces? Our bead blasting services deliver a clean, satin finish that’s perfect for both precision components and decorative projects.

Get a quote